Katalogauszüge

The cleanest ÖkoFEN pellet heating system ever 1

Katalog auf Seite 1 öffnenOur claim: Better and better The world's first type-tested pellet heating system, pellet condensing technology, the fabric tank with flexible sloping floor and electricity-generating pellet heating systems - since 1997, our claim has been to be the innovation leader in pellet heating technology. Our motto is not to bring the first available ideas to the market, but always the best. We always think ahead and put our own developments to the test again and again. 2

Katalog auf Seite 2 öffnenThe logical way: Always cleaner The purity of the air has always been a major concern for us. With the clean ZeroFlame® technology, ÖkoFEN has succeeded in reducing dust emissions to an absolute minimum. Thus, we have once again achieved a decisive milestone and continue to follow our path: Always better, always cleaner in pellet heating technology. 3

Katalog auf Seite 3 öffnenMaking the invisible visible: The exhaust air is so clean that nothing can be seen. Only with the help of a cold object the water vapor can be made visible.

Katalog auf Seite 4 öffnenThe result: The cleanest ÖkoFEN pellet heating system ever The amount of dust that leaves the highly efficient pellet heating system is hardly measurable. With our latest development, we make a significant contribution to the purity of the air. Best values under practice conditions TÜV Austria tested this cleanest ÖkoFEN pellet heating system: In a cycle test, which simulates the various operating conditions over the course of an entire year, an average of only 2 mg/m3 (13% O2) of dust emissions was measured.

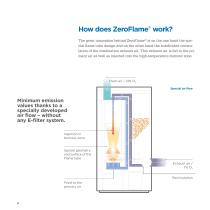

Katalog auf Seite 5 öffnenHow does ZeroFlame® work? The great innovation behind ZeroFlame® is on the one hand the special flame tube design and on the other hand the subdivided recirculation of the combustion exhaust air. This exhaust air is fed to the primary air as well as injected into the high-temperature burnout zone. Fresh air / 21% O2 Special air flow Minimum emission values thanks to a specially developed air flow – without any E-filter system. Injection in burnout zone Special geometry and surface of the Flame tube Exhaust air / 7% O2 Recirculation Feed to the primary air

Katalog auf Seite 6 öffnenFeuer neu erfunden – Fire reinvented Due to the specially developed air stream, a fire arised - WITHOUT A FLAME. Thereby the fine dust particle emissions are reduced to a minimum. The result: Heat and clean exhaust air WITHOUT ZeroFlame® Regular low dust firing WITH ZeroFlame® Dust emissions close to zero The comparison of the two technologies shows that the combustion of pellets is even cleaner thanks to ZeroFlame®.

Katalog auf Seite 7 öffnenConvincing in practice The 9h load cycle test, which also takes into account start, stop and modulating phases, simulates the heating operation over an entire year. Even with changing - so-called dynamic - power consumption, the average emission value remains well below the permissible measurement uncertainty for practical measurements. Test reports of comparable boilers achieve equally good values, but often only with static power consumption under best conditions, i.e. at the moment of testing, and not during operation, as shown by the load cycle test. The particulate matter Static type...

Katalog auf Seite 8 öffnenClean - completely without filters The ZeroFlame® technology convinces through: Clean wood combustion for best air quality No high-voltage particulate filter necessary Always in operation, even in start and post run phases No additional maintenance, safe to operate Reliable technology and simple construction

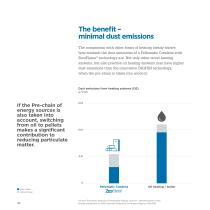

Katalog auf Seite 9 öffnenThe benefit – minimal dust emissions The comparison with other forms of heating clearly shows how minimal the dust emissions of a Pellematic Condens with ZeroFlame® technology are. Not only other wood heating systems, but also practice oil heating systems may have higher dust emissions than the innovative ÖkoFEN technology, when the pre-chain is taken into account. Dust emissions from heating systems (DE) g/kWh If the Pre-chain of energy sources is also taken into account, switching from oil to pellets makes a significant contribution to reducing particulate matter. Pellematic Condens...

Katalog auf Seite 10 öffnenWhile other filter systems use electrostatic precipitators to reduce dust emissions, pellet combustion can, with very effective and comparatively simple measures avoid fine dust almost completely. A comparison with other everyday sources of fine dust clearly shows: ZeroFlame® technology is clean even over the course of a year. For example, a pellet boiler with this technology emits only about one tenth of what the tire abrasion of an average passenger car causes. Practical dust emissions from wood-fired heating systems in mg/m3 at 13 % O2 Dust emissions per year (DE) 1 cup = 600 g Ø Wood...

Katalog auf Seite 11 öffnenMore information about this new and innovative technology under oekofen.com Explanatory video for the ZeroFlame ® Technology Austria - Headquarters ÖkoFEN Forschungs- & Entwicklungs Ges.m.b.H. A-4133 Niederkappel, Gewerbepark 1 Tel.: +43 7286 74 50 E-Mail: info@oekofen.com www.oekofen.com Germany ÖkoFEN Heiztechnik GmbH Schelmenlohe 2 D-86866 Mickhausen Tel.: +49 82 04 29 80-0 E-Mail: info@oekofen.de www.oekofen.de Switzerland ÖkoFEN-Schweiz GmbH Rüdel 4 CH-6122 Menznau Tel.: +41 41 493 04 55 E-Mail: info@oekofen.ch www.oekofen.ch Italy ÖkoFEN Italia Srl Via Peter Mitterhofer 23 I-39025...

Katalog auf Seite 12 öffnenAlle Kataloge und technischen Broschüren von Oekofen

- Pellematic© Condens 22 - 32kW

12 Seiten

- Pellematic© Condens 10 - 18 kW

12 Seiten

- Green Heat from Wood Pellets.

20 Seiten

- Wärmepumpe

- Heizkessel

- Heizkessel für den Innenraum

- Wohnbereich-Heizkessel

- Luftwärmepumpe

- Wohnbereich-Wärmepumpe

- Wärmepumpe für Außenbereich

- Solarpanel

- Warmwasserbereiter

- Vertikaler Warmwasserbereiter

- Split-Wärmepumpe

- Kondensationsheizkessel

- Heizkessel / nur für Heizzwecke

- Energieklasse-Heizkessel

- Heizungsregler

- Pellet-Heizkessel

- Thermischer Sonnenkollektor

- Heizkessel für professionellen Gebrauch

- Heizkessel mit Warmwasserbereiter

- Holzheizkessel